DFM Design For Manufacturing In China

We are A 18 Year’s Old Innovative Industrial Design Company And We Are The Largest Design Company In China.We provide one-stop product development services, including industrial design, mechanical design, Electronic Design(Hardware), firmware design, rapid prototyping,small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

HOW TO DESIGN A PRODUCT THAT’S EASY TO MANUFACTURE – 5 KEY POINTS

The number of new products that fail every year is crazy; some make it to market launch, flop, and some don’t even make it into mass manufacturing because of lack of budget or manufacturing-related issues.

The good news is that we’ve also worked with companies that have had a successful product launch and have recurring sales. A significant part of their success is thanks to a product design that’s easy to manufacture.

So, the one million dollar question.

Some put the failure rate of new products as high as 97%

Honestly, I’m not surprised. We’ve been in the electronics product manufacturing business for years, and we’ve seen companies make the same mistake repeatedly.

How to design a product for manufacturing? More specifically, how to design a product that will make a smooth transition between final prototype and mass manufacturing.

While we focus on electronics product design and manufacturing, these principles apply to any product you’re working on.

1 – LEARN ABOUT DESIGN FOR MANUFACTURING

DFM is a product development strategy that focuses on including all relevant parties as early as possible in the design stage.

- Designers

- Engineers

- Manufacturing partners

- Sourcing specialists

- Marketing manager

- other relevant parties

If you bring everyone together from the start, you’ll ensure your product design is something the factory has enough expertise to manufacture. The sourcing specialists will let you know whether the components and parts you’re choosing are easy to get and at what price.

If your product has moving parts, a mechanical engineer needs to be there early in the design stage; they’ll let you know how easy/difficult it’ll be to make the product move the way you want it to.

2- LEARN THE COSTS TO TAKE A PRODUCT FROM DESIGN TO MANUFACTURING

Before you go on a holiday, you probably do a budget. You make a list of all the things you’ll spend money on, flights, hotels, tours, restaurants, taxis, visas, etc…

Otherwise, you run the risk of running out of money halfway through the trip and getting stuck in a tricky situation.

In a situation like this, you’d probably call somebody to transfer some money to you, and you’ll make your way back home; problem solved.

Well, in product design and manufacturing, if you run out of money halfway, chances are that’s it your product is dead. Unfortunately, it’s happened to countless start-ups.

Many underestimate manufacturing costs.

Injection molding alone, which any new product will need, can cost up to $1 Million, that’s right, a million.

The cost of the injection molding is directly affected by the product’s shape; that’s right, the form you/your team decided on when designing the product.

Hence the importance of having a clear understanding of manufacturing costs and what design decisions affect them.

Here’s one design guideline for more affordable plastic injection molding

Use a uniform wall thickness throughout the part and avoid thick sections. This is essential since non-uniform walls can cause deformation or the part as the molten material cools.

LIST OF MANUFACTURING COSTS TO BE AWARE OF

- Electronic architecture

- Industrial design

- Mechanical engineering

- Firmware/software development

- Prototyping

- Tooling/Plastic Injection

- Certifications

How much money does all of this cost? The answer is it depends; it’s very circumstantial.

We do have a calculator that can help you figure it out; we call it non-recurring engineering calculator.

3 – TO GO FROM DESIGN TO MANUFACTURING IT’S IDEAL TO HAVE AS FEW PARTS AS POSSIBLE.

Here’s a photo that illustrates this point very well. Design for manufacturing examples

On the top, you have something resembling a TV box, a simple design product, a simple square box; it doesn’t get simpler than that.

The injection molding for the top and bottom case was probably cheap; perhaps they even used a generic mold that already existed.

This is the kind of product whose design is easy to take into mass production; people down the assembly line will have very little concern when putting such a product together.

On the bottom of the image, you have the Juicero, a beautiful design but difficult and expensive to take into mass production.

The door system alone had dozens of components that needed careful assembly, and all the molds were custom made, ensuring a high manufacturing cost.

This is one of the reasons that killed this fantastic ( not helpful) piece of engineering.

Also, having a product with few pieces to assemble makes it fast and cheaper to assemble.

Think of a 10 pieces jigsaw puzzle vs. a 1000 pieces one; obviously, the latter will be faster to assemble correctly; and if you had to pay someone to assemble it for you, they’d charge you way more for the 1000 pieces one, correct? Because it’ll take longer to assemble it correctly.

Now, I understand that in some instances, some products require many parts, even moving parts.

In this situation, all I can say is, please understand your design and manufacturing costs very well and read on Poka Yoke, a term that refers to mistake-proofing an assembly process.

Humans make errors, so better to mistake-proof the assembly line.

So Far. We know that to come up with a design that’s easy to manufacture, you should

- Involve all parties early in the design stage

- Understand all the costs of your product and how the product design affects them

- Design a product with as few parts as possible; it’s easier for the manufacturer to assemble it

4- TESTING YOUR DESIGN THROUGH PROTOTYPING

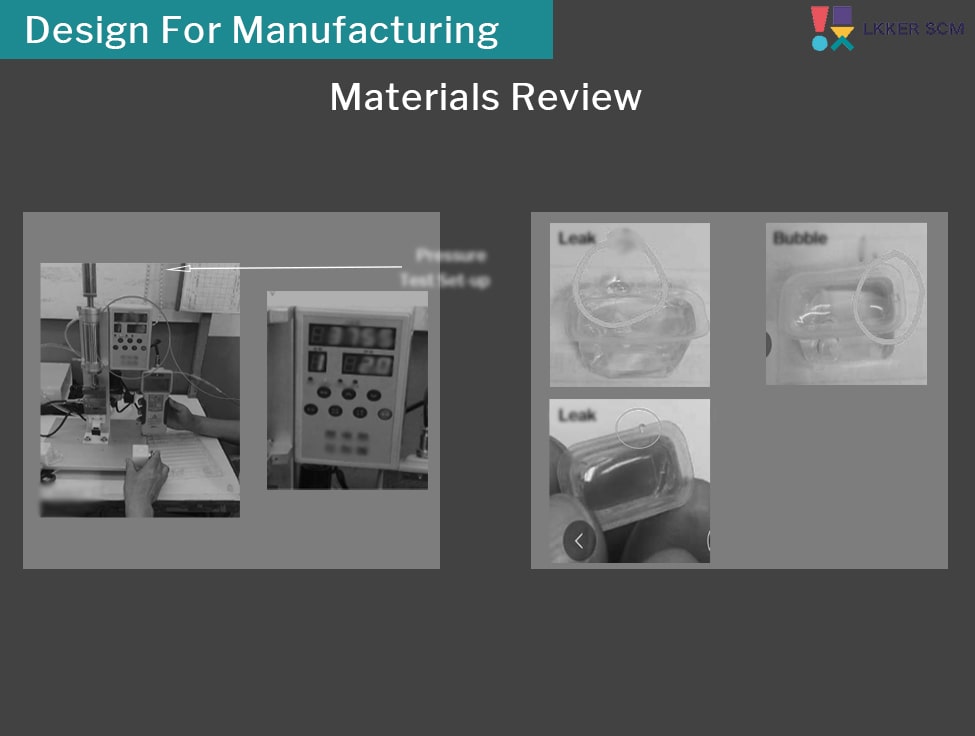

An excellent design for mass manufacturing means that your product design meets your target audience’s wants and your manufacturing company’s capabilities; you make sure both are positive by prototyping.

The prototyping stage has many stages; depending on its complexity, a product can go through dozens of versions until you get to the version that is ready for mass manufacturing; the latter plus the proof of concept are the ones I’m going to focus on here.

You want to design a product for manufacturing because you’re looking for business; small business, big business, it doesn’t matter; you want to make money.

So here’s a thought you should always keep in mind.

All the engineering, manufacturing process, look and feel, from initial sketch to final design and final product, can be exactly what you want. We can do it; if you have the money for it, we’ll mass-produce it.

But will it sell?

Not necessarily; look at the Juicero for a real example of a beautiful design and manufactured product that failed.

It would be best to only move into a serious prototyping stage once you answered the following problems.

- Who is our target audience?

- What is the size of the market?

- Who would be the competitors?

- Is there a need for our product?

That last question is fundamental.

We’ve seen many start-ups get caught up in their product idea; they swear by their great idea and go on designing and onto manufacturing without doing a serious market study that proves there’s a need for their product.

You make sure the market wants your product by doing a proof of concept; think of it as your first prototype; by no means it has to be a fully developed product.

Use Off the shelf parts and test your market hypothesis; you can read a case study here.

You can use 3D printing for a quick prototype.

The point here is to go from a general idea of something that could sell to concrete evidence that this new idea is worth going after until it becomes a finished product.

After you prove this, how many prototypes will you need until you have the ready-to-manufacture prototype? Well, many.

The last one is the Golden sample, the one that’s ready to be mass-produced.

Throughout the process, different components, parts, features have been tested, added, or dropped.

You need to have a looks-like, works-like product that will satisfy the end-user and the manufacturer.

If you followed a design for manufacturing approach, this wouldn’t be a big deal as the product will have been created with the participation of your manufacturing partner, ensuring a product design that’s easy to manufacture.

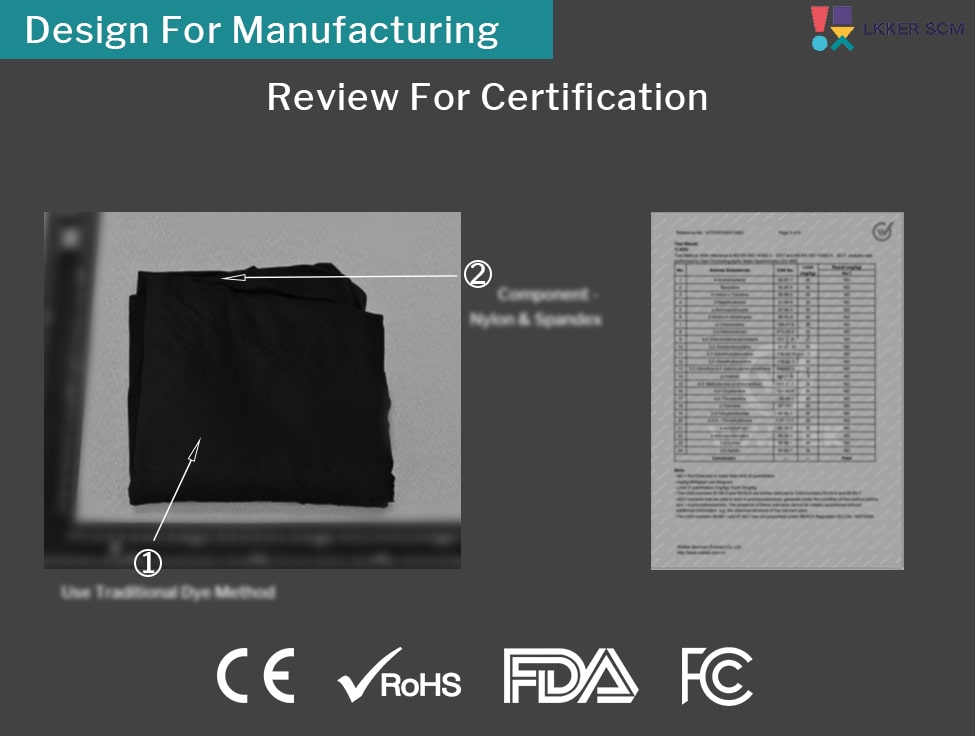

The final prototype will also have passed certification testing; depending on the environment, characteristics, and region where the end-user will use it, it’ll have to undergo different certification testing.

So Far. We know that to come up with a design that’s easy to manufacture, you should

- Involve all parties early in the design stage

- Understand all the costs of your product and how the product design affects them

- Design a product with as few parts as possible; it’s easier for the manufacturer to assemble it

- Do a prototype/proof of concept to make sure there’s a real need for your product

- The prototyping stage will move along with the manufacturer’s input to ensure a final prototype easy to manufacture

There’s one more thing you have to pay special attention to end up with a product design that’s easy to manufacture.

5- COMPONENTS AND PARTS FOR A SMOOTH MANUFACTURING PROCESS.

I’m about to explain, presently, might be more relevant for electronic products; but the core applies to any product.

Make sure that the components and parts you are using for your product design are available.

Look, after doing everything we’ve mentioned so far.

- Including all relevant parties early in the design stage

- Learning what kind of design increases or decreases a specific design and manufacturing cost

- Reducing parts and components in your design to the minimum

- Doing all the proper prototypes to validate your business idea with input from your manufacturer along the way.

You could still end up with a design that would take years to manufacture – the reason is Components shortages.

As of now, in November 2021, some electronic components’ lead times are up to 52 weeks; that’s putting many electronic projects on hold.

Then again, if your product doesn’t fall within the electronics category, you might be fine; but if you’re working on an electronic device, then pay a lot of attention to the news, check with components suppliers for the lead times of the critical components of your design.

The earlier you know which components are readily available and which aren’t, the better your design will be as you won’t have to remove components along the way and redesign.

If your core components are scarce and you find out deep into your prototyping testing stage, you might end up going back to stage one of the design, and you’ll have to start the prototyping from zero.

HOW TO DESIGN A PRODUCT FOR MANUFACTURING – CONCLUSION

Many posts out there will tell you to follow a linear structure, start with product research, move to design, prototype, and then get somebody to manufacture your design the way you want/need it to be.

I’m sorry, but this is the advice from someone who has never worked on a design and manufacturing project.

That’s a recipe for disaster.

The right way to design a product for manufacturing, which will be easy to manufacture, is to take a holistic approach.

Involve every relevant party early in the design stage and follow best practices

- Learn about manufacturing costs

- Reduce parts and components in your design

- Do an early proof of concept

- Find out the lead time of your components

RELEVANT QUESTIONS

HOW DO I PROTECT MY INTELLECTUAL PROPERTY?

How to? Well, you make the people you’ll be working with sign an NDA agreement, non-disclosure agreement.

Please have a look at the one we sign before we start working with a new client.

Further Reading to design a winning electronic.

Get DFM Product Review Feedback in 7-10 working days

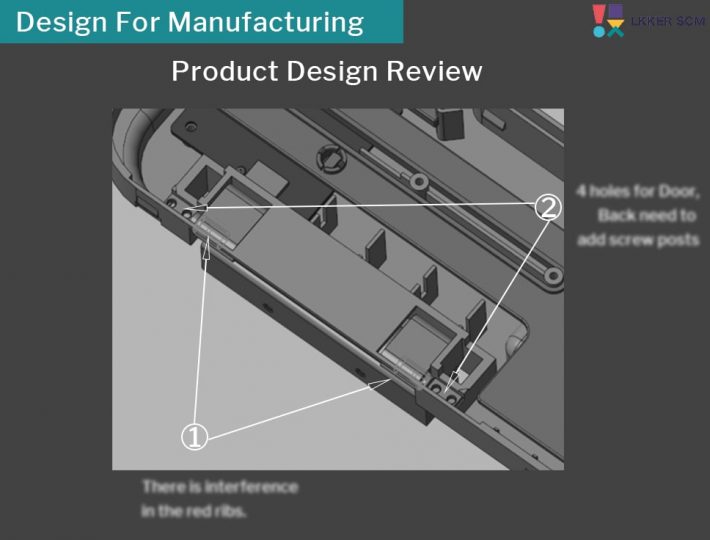

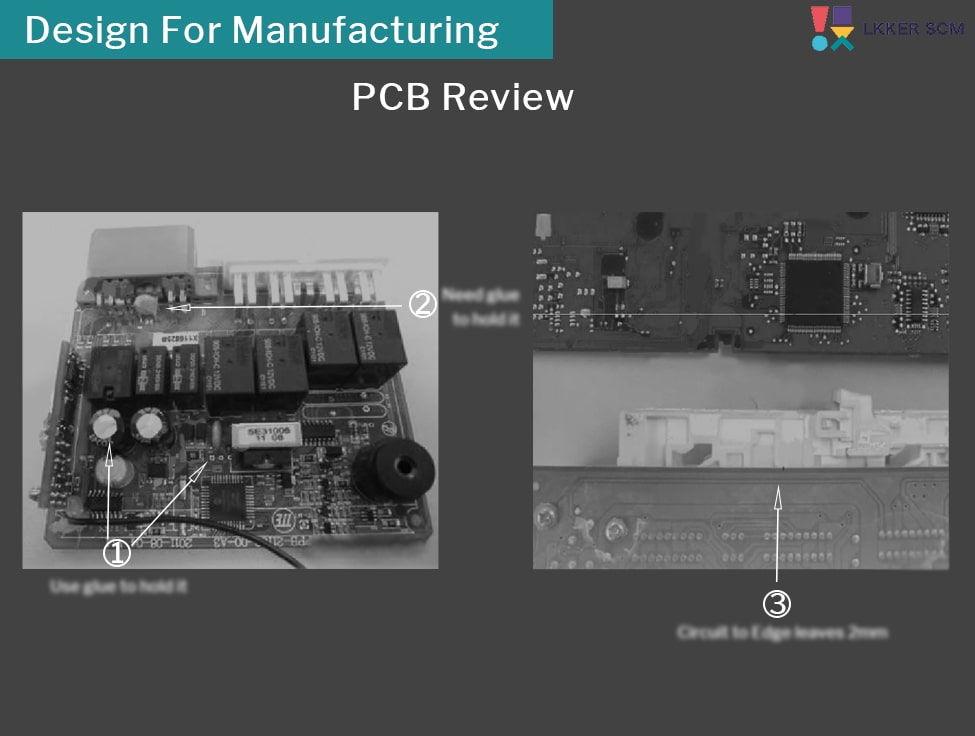

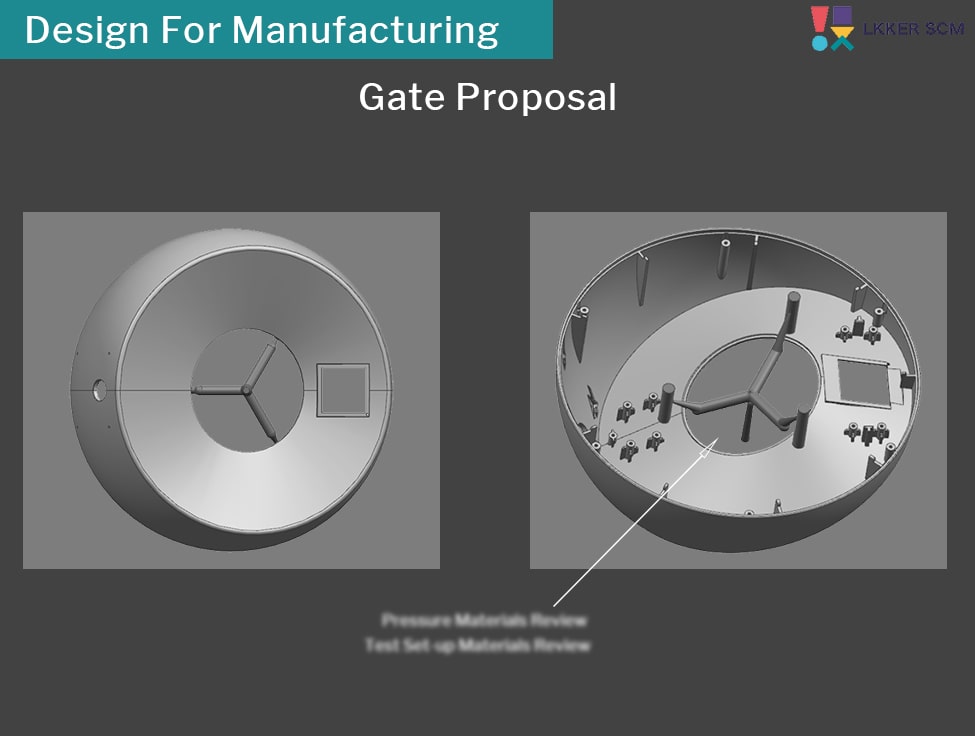

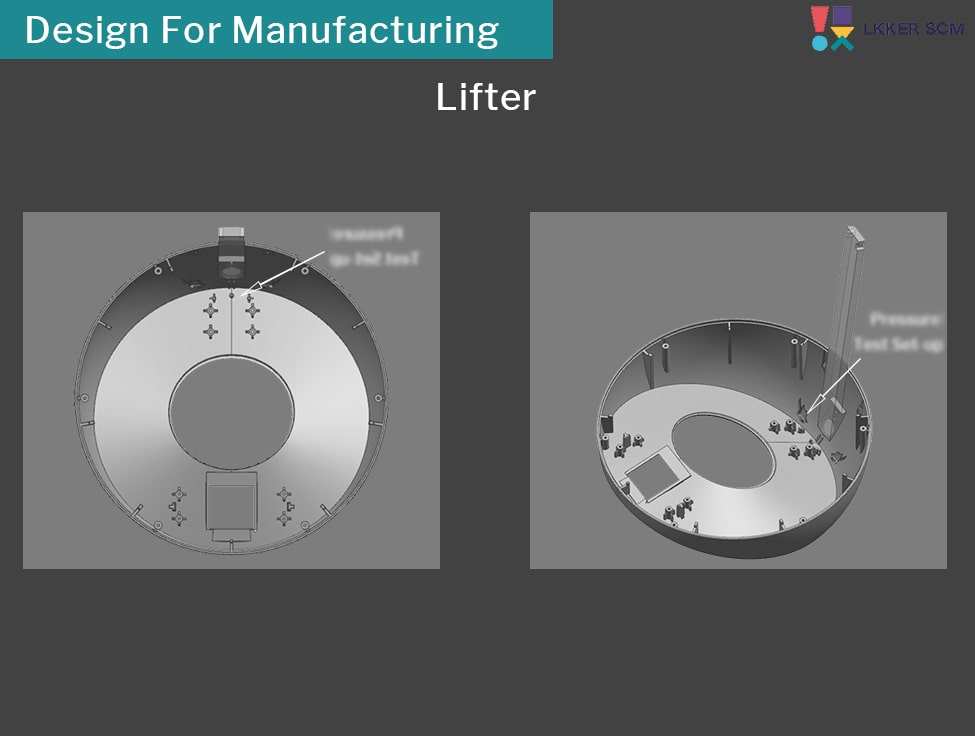

No matter what your product stage is (suggested below), LKKER SCM will conduct a product review mainly on industrial design and mechanical design for manufacturing feasibility. This is to help you identify problems in design and correct them before mass production implementation.

conceptual product mock-up | sketch 3d renders product review | POC prototype | MVP prototype product review | the final product.

We Build Confidence In Your Design.

LKKER SCM project managers and product engineers, due to their years of product manufacturing experience, can build some of your design for manufacturing work into earlier phases. We provide the next deeper level of product design necessary to make products that can be mass-produced economically. When doing design for manufacturing, there really is no substitute for experience.

Don’t Do It Too Late In The Product Development Process.

To achieve the best design for manufacturing (DFM) purpose, a product review is done ideally after concept development is frozen. Or, do it after several rounds of prototypes have been built, and enough testing has been done. It could be quite costly if the design for manufacturing (DFM) is done after mold making.

The Key: Industrial Design Review And Mechanical Design Review

LKKER SCM will utilize technical know-how to review your product design, industrial design, mechanical design, software, and hardware integrations from the perspective of product manufacturing feasibility. The industrial design and mechanical design will highly affect the manufacturing process, how a part should be produced, finish requirements, required tolerancing, and assembly process.

Design For Manufacturing (DFM) Review List

Design Modifications For Easy and Economical Mass Production

LKKER SCM will work on industrial design and mechanical design improvements. We contribute value in better product quality, lower product cost, shorter product manufacturing time, less operational efforts, fewer technical difficulties, and full supply chain resources optimization. For example, a typical LKKER SCM product review report for a product prototype will include assembly interference analysis, draft, and thickness analysis with design modification suggestions.

Other Services

Industrial Design Services

-

Supplier Matching Service

-

Project Management

-

Certification

-

DFM Design for Manufacturing

-

Mechanical Design Services

-

Electronic Design Services

Develop product hardware and card software; standardize hardware development processes; control hard...

-

Rapid Prototyping China

Rapid prototype For Consumer Electronics. Get your free, instant quote.

-

Injection Molding Service

-

Small Batch Production

-

Packaging Design Services

-

Mass Production

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025

The Designer Festival was successfully held at LKK Design

News April 2025

LKK Design Ushers in a New Chapter in Shenzhen: Driving Strategic Growth Through Product Design

Technical October 2024

LKK Design participated in the 90th Shenzhen International Medical Exhibition

News October 2024