We are A 18 Year’s Old Innovative Industrial Design Company And We Are The Largest Design Company In China.We provide one-stop product development services, including industrial design, mechanical design, Electronic Design(Hardware), firmware design, rapid prototyping,small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

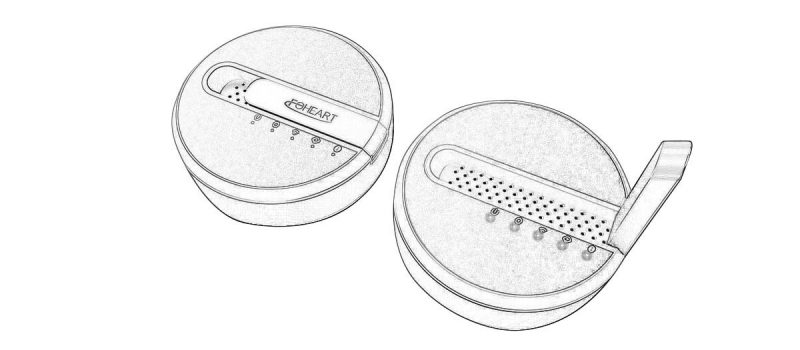

AESTHETICS AND ERGONOMICS

Electronic Product Industrial Design (ID) is a key factor in the commercial success of a product and every product design should start with research; who are the end-users, how will they use the product, what are the key benefits they are looking for, and what kind of styling will seduce them? Our goal is to have the end-users rave about the new product to their friends, and often we achieve this not so much with the specifications as with the Aesthetics and Ergonomics. The mission of our industrial designers is to design a product which visually attractive and a joy to use, the two keys to selling more products. Our industrial designers work side by side with our mechanical and electronic engineers to ensure that the product design will not only meet its aesthetic and ergonomic targets but is also easy to manufacture in China. Our team also has extensive experience working with overseas industrial designers, so we welcome cooperation with product design firms.

END-USER DESIGN

At the onset of every design project, our designers do extensive research into the basics— – Who are your end-users? – How will your product be used? – What does the design need to communicate?

ID

The main aspects of marketability are design and ergonomics. Design is about esthetics. If your product does not look appealing, it will not sell. The value of a good industrial design is crystal clear: an attractive design not only helps to sell more products, but it also allows you to charge higher prices, which means that the actual profit per unit can be a multiple of the profit on a so-so looking product. Ergonomics, on the other hand, focuses on human interaction with a product: How does it feel in your hand? Do the shape and contours conform to the part of the body that comes into contact with the device? Our designers have the skills and the experience to design products in which the design and ergonomics work together to deliver an attractive, easy-to-use product.

DESIGN FOR MANUFACTURING

While design and ergonomics are instrumental in making a product marketable, they alone do not guarantee success. Careful consideration of production in the initial stage is crucial because a sizeable percentage of the product’s lifecycle cost is committed at this time (cost of materials, production of parts, and assembly). Titoma’s designers integrate design and industrialization into a single process, with the goal of designing a product that is easily and economically manufactured. This is achieved by early collaboration with mechanical and electronic engineers and production specialists to produce a design that fulfills price and manufacturing parameters.

THE BASIC GUIDELINES OF OUR INDUSTRIAL DESIGNERS ARE:

1. LESS IS MORE

One of the best methods for reducing manufacturing costs is to reduce the number of parts in a product. Fewer parts often lead to less sourcing, development, purchasing, assembly, testing, development time, and testing, among others.

2. MAKE IT MODULAR

The use of modules in product design significantly reduces the level of intensity of manufacturing-related activities. In addition, it provides ease in repairing, maintaining, or replacing a part of the device in the event the part were to fail.

3. USE STANDARD COMPONENTS

Standard components are naturally less expensive than custom-made ones. The availability of these components means reduced lead times—the amount of time it takes to procure components. Using standard parts also offers peace of mind with regard to the components’ reliability.

4. KEEP IT SIMPLE

To minimize manufacturing cost, we select the optimal combination between material and fabrication process. Secondary operations such as painting, coating, and surface finishing should be avoided as should a high degree of precision on parts. These pose manufacturing challenges and increase the reject rate (yield loss), resulting in higher part production cost. That is why our designer design with ease of fabrication in mind.

5. ROUND IT UP, GIVE IT AN ANGLE, AND DON’T FIGHT GRAVITY

Use rounded corners as opposed to sharp angles since plastic flows better through rounded corners during plastic injection. Concurrently, (draft) angles—an angle incorporated into a wall of a mold so that the opening of the cavity is wider than its base—are needed so that a plastic part can be released from the mold without damage. In addition, a design minimizing assembly directions. Electronic products should be assembled from one direction— ideally from above. This way gravity works with you during the assembly process as opposed to slowing down assembly by having to compensate for its effect.

From Concept to Product Design Workflow

Ready to Meet With Our Designers?

LKK Product Innovation Group Founders’ Point of View

FanCong Li

FanCong Li

General Manager of LKK Design

“In the process of product polishing, the role of product design is to be the explorer of innovation. In the future, technology must be made more human-centered through product design. Technology will become more user-friendly, easier to use, lower in cost, and truly serve users through product design. This is the real value of product design. We are currently exploring the specific application of “technology + design”, using technology to amplify the boundaries of design.”

David Wei Jia

David Wei Jia

Founder of LKK Design

“A good product also has three views: user view, values, and world view. User view determines whether a product shall be made, values determine whether a product can be made successfully, and world view determines whether the product can be sold.”

Xiangchi Li

Xiangchi Li

General Manager of LKK R&D

“Combining the two core elements of “design” and “R&D supply chain” to open up the upstream and downstream of “creating good products”, and coordinate social resources to build a digital ecosystem for the entire product life cycle”

James ZeMao Deng

James ZeMao Deng

General Manager of LKKERSCM

“Good ideas are easy, the hard part is how to implement them. There are two groups of people in our team, one group is designers and the other group is engineers. Designers look up to the stars and engineers are down-to-earth. Making a product is a process of constant compromise. Designers and engineers have to constantly compromise with each other.”

Other Services

October 2024

Industrial Design Services

-

Supplier Matching Service

-

Project Management

-

Certification

-

Electronic Design Services

Develop product hardware and card software; standardize hardware development processes; control hard...

-

Rapid Prototyping China

Rapid prototype For Consumer Electronics. Get your free, instant quote.

-

Injection Molding Service

-

Small Batch Production

-

DFM Design for Manufacturing

-

Mechanical Design Services

-

Packaging Design Services

-

Mass Production

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025

The Designer Festival was successfully held at LKK Design

News April 2025

LKK Design Ushers in a New Chapter in Shenzhen: Driving Strategic Growth Through Product Design

Technical October 2024

LKK Design participated in the 90th Shenzhen International Medical Exhibition

News October 2024