1. Project background

Jiangxi Hongdu Machinery Manufacturing Co., LTD., a company with deep accumulation in the field of agricultural machinery, decided to develop a new type of weeder in order to adapt to the changing market demand and improve product competitiveness. In the process of looking for a partner, LKK Design, with its excellent design strength and research and development experience, successfully obtained this project.

2. Product design

User needs research: Before the project begins, the Design team at LKK Design has an in-depth understanding of the needs and expectations of the users. Through market research and user interviews, they conduct a comprehensive analysis and summary of the needs of users. Considering the actual needs and expectations of users, the design team focused on efficient weeding, ease of operation, comfortable experience and environmental performance.

Innovative Design: Based on user requirements and the results of market research, the design team of LKK Design came up with an innovative design solution. The scheme not only meets the basic needs of users, but also introduces some new functions and design elements to make the weeder more intelligent and efficient. By introducing advanced science and technology and innovative design concepts, they optimize the structure and use experience of the weeder. Hyperboloid mech wind modeling, high cost, difficult to achieve. Designers through three-dimensional software simulation in the early stage, the later several proofing and debugging, to provide customers with a low cost of streamlined hyperboloid mech wind modeling, design innovation to promote the commercial transformation of products.

Humanized Design: Manual mowing environment is harsh, labor intensity is high, in order to improve the user experience, LKK Design pays attention to the optimization of human-computer interaction in the design. They optimize the operation interface, simplify the operation process, provide intelligent tips and guidance, etc., so that users can be more convenient and fast to use the weed mower. At the same time, they also pay attention to the user's comfortable experience, from the driver's seat, operation handle to safety protection and other aspects of the detailed design. The final completed unmanned lawn mower can reduce the labor intensity of workers, the operator can monitor the operation of the unmanned lawn mower in the monitoring room, and one person can monitor multiple units at the same time.

Performance Design: While meeting user requirements, LKK Design also optimizes the performance of the weeder. They improved the weeding effect and efficiency of the weeding machine by improving the material and shape of the blade and optimizing the power and speed of the machine. At the same time, they also pay attention to the energy efficiency of the weeder, through the optimization of the design and the selection of efficient motors and other measures to reduce energy consumption.

Environmental Design: In the design, LKK Design also pays attention to the embodiment of environmental protection concepts. They minimize the environmental impact of the weeder by using environmentally friendly materials, optimizing energy use, and reducing noise and emissions. At the same time, they also take into account the recycling and disposal of waste parts to achieve the recycling of resources.

3. product development

Prototyping and testing: After the product Design phase, LKK Design collaborated with Hongdu to build a prototype for field testing. During the testing process, they simulated various practical use scenarios and conducted rigorous testing and evaluation of the prototype. According to the test results, they further optimized and improved the design scheme. Improve product design and performance through continuous testing and improvement.

Production preparation: After many prototype tests and improvements, Hongdu started the production preparation work. LKK Design provided production process guidance and material suggestions to assist Hongdu in setting up the production line and ensuring the smooth running of the production process. At the same time, they also strictly monitored and managed the environmental impact of the production process to ensure the quality and environmental performance of the products.

Quality control: In the production process, Hongdu Company has implemented strict quality control measures. Through the quality control of raw materials, the production process, the monitoring and testing of finished products, etc., they ensure that every weeder delivered by the factory meets the company's quality standards. Through strict quality control measures, the quality and reliability of products are guaranteed.

Product listing: After a series of development and preparation work, Hongdu company's weeder finally went on sale with its innovative design, efficient performance and high-quality user experience, the product quickly won market recognition and praise as the first unmanned mowing equipment for airports in China, it has high work efficiency, strong environmental adaptability, easy maintenance and other characteristics, and now serves Beijing Daxing Airport and Yao Lake Airport, Qingyunpu Airport, Chengfei Airport, Yangcun Airport, etc. Through practical applications and market feedback, the innovative design and high-quality performance of products have been recognized and praised by users, which has promoted the expansion of the market and the expansion of the application range.

In SUMMARY

In this case LKK Through innovative Design concepts and methods, DESIGN successfully helped Hongdu company to develop a competitive weeder product. They deeply understand the market needs and user needs and use advanced technology and materials to meet the basic needs of users while improving the overall quality and competitiveness of the product through innovative design, humanized design, performance optimization and environmental design With the help of strict production process and quality control measures to ensure the quality and reliability of the product, the successful listing of the product and the promotion of market recognition have demonstrated the professional ability and strength of LKK Design in the design development and productization, and injected new impetus into the development of agricultural machinery field.

We provide one-stop product development services:industrial design, mechanical design, rapid prototyping, small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

Others Cases

-

Smart Aquatics Feeding Machine

Innovative solutions for modern aquaculture industry

-

Home Vegetable Planter

The perfect combination of technology and green

-

Innovative Dog Harness

We are not able to show more product images or disclose the names of our clients...

-

Smart Car Sunshade

We are not able to show more product images or disclose the names of our clients...

-

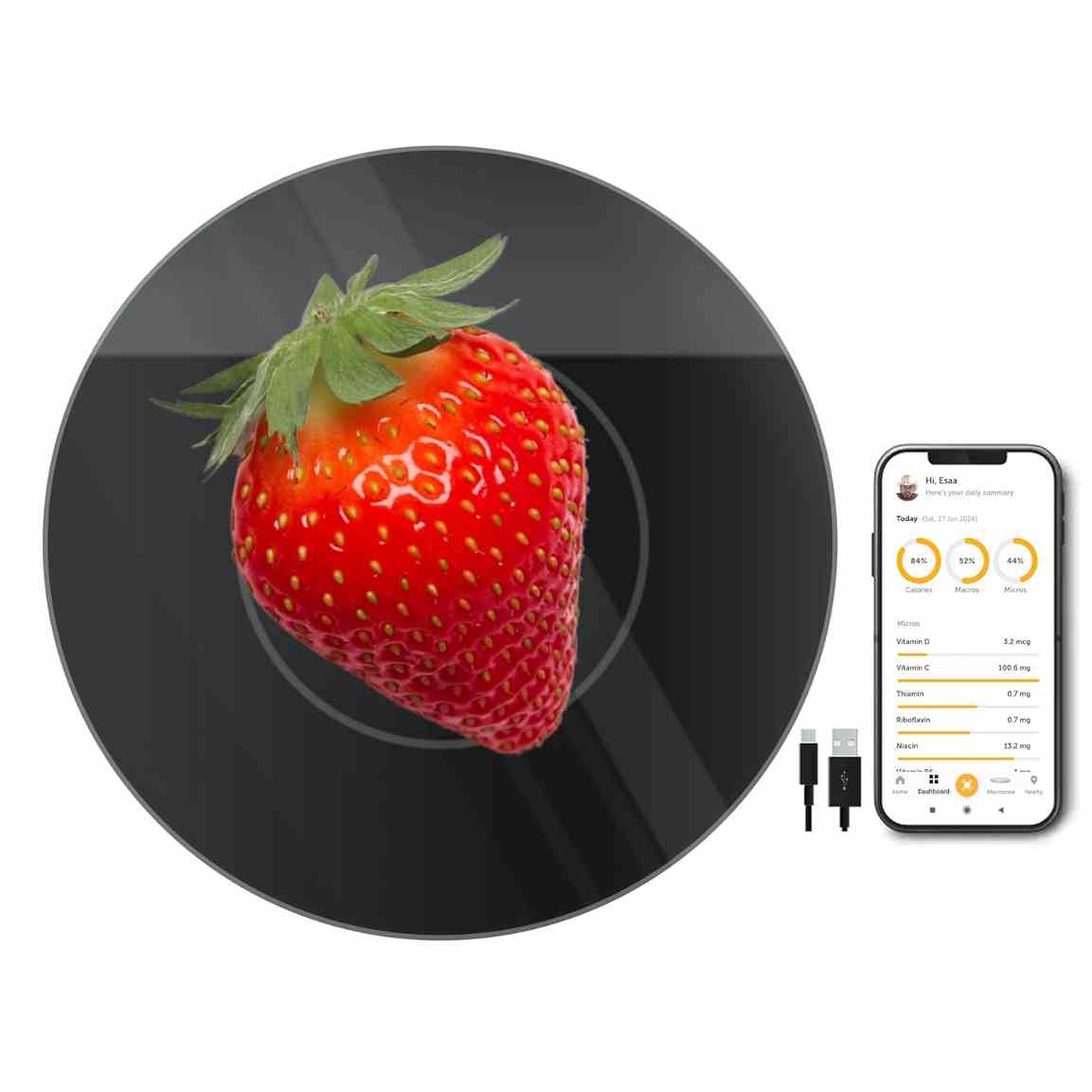

Smart(IOT) food scale

Product design and development of smart Bluetooth kitchen food scale

-

Shawllar Power Adventure - Outdoor

105W Power Adventurer series

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025

The Designer Festival was successfully held at LKK Design

News April 2025

LKK Design Ushers in a New Chapter in Shenzhen: Driving Strategic Growth Through Product Design

Technical October 2024

LKK Design participated in the 90th Shenzhen International Medical Exhibition

News October 2024