Project Background:

Jiangsu Kangshang Biomedical Technology Co., Ltd. is an innovative technology company focusing on family medical care, clinical medical care, Internet medical care and big health ecology. Oxygen generator is a kind of equipment based on compressed air separation technology to separate gas molecules to produce ultra-high purity oxygen. With people's increasing concern about health problems and environmental pollution, oxygen generators are becoming more and more people's choices, and at the same time, oxygen generators have also become one of the hot products for industrial production.

User requirements:

The commissioned design project is a medical oxygen generator, because the form of oxygen generator on the market is too similar, the customer hopes to break away from the traditional appearance, design the oxygen generator with new thinking, and increase the way the product is used and the visual experience is comfortable.

Market Research:

The design fully considers the user's operation process and working experiment environment, greatly improves the portable and home product attributes of the equipment, differentiates from the products on the market, and enhances the brand image of the enterprise.

Product Strategy:

The design direction is simple and portable, hoping that the product can be more gentle and shorten the user's experience distance, while simplifying, we open the gap in form in the market, so that Kangshang products can be more significant in the market;

User Experience:

In terms of operation experience, the design concept of full screen is adopted, which greatly improves the visualization and convenience of products;

Optimize the experience:

The side of the product is designed with modular accessories, which can be configured according to the medical scene, so that the audience medical institutions are wider;

solution

- In the industrial design process, the Rococo team provided appearance design services for Kangshang Biomedical this time, in the early stage of design, we fully considered the cumbersome and inconvenient use of traditional oxygen generators, and improved the experience of medical staff in use; From the user's point of view, the designer should stand in the user's point of view, taking into account the shape, size, material and other factors of the model, in order to meet the user's aesthetic and practical needs. After preliminary sketch design and market research, the product designer completes the prototype design and prepares it for the next structural design.

- Structural design link. In this link, the prototype design should be further implemented, and the component layout and assembly method inside the body should be determined through the design of the structure to ensure that the performance and use effect of the machine are better. Even a very small structural design requires careful consideration in order to increase production efficiency and reduce production costs in series production in the future.

- In the prototype production stage, the factory will make a prototype like industrial design and structural design drawings based on the product renderings, 3D files and BOM tables designed by the designer , to verify the results of the design phase and check whether the prototype meets the customer's needs in terms of appearance and function.

- In the mold making stage, the factory starts to design the mold according to the design drawings, and DFM (Design for mold) will be carried out before the mold design Evaluate the feasibility of design drawings from all aspects related to mold design and production, including parting, inlet, ejection mechanism, molding process, post-processing process such as oil injection and screen printing, production efficiency and cost. After the completion of the mold design, the entire mold manufacturing and improvement process will be followed up to ensure the mold quality and manufacturing cycle, while verifying and continuously optimizing the early product design to ensure the quality, cost and delivery time of subsequent product mass production.

- The low-volume pilot production stage, which is an essential step for manufacturing companies before releasing new products. It can measure the quality of the product, the cost of the production process, and the feasibility by prototyping several prototypes. In the small batch trial production stage, the manufacturer will improve and confirm most of the process information, and optimize the production process through a certain degree of technical adjustment, improve production efficiency and reduce production costs. When the production process and process flow are approved and validated, the manufacturer can conduct small-scale production testing. The output at this stage is usually tens to hundreds of pieces, and this magnitude covers all aspects of the trial production process. In accordance with strict product standards, manufacturers conduct multiple tests and tests to determine the reliability and durability of products. Manufacturers need to record all production data and evaluate all loss and cost data so that you can refer to this data when expanding production later. Low-volume trial production is an inevitable part of the entire product development process of manufacturing enterprises, and this stage is the necessary preparation for large-scale production. In the pilot production stage, manufacturers can accurately evaluate the advantages and disadvantages of the product process, and give necessary modification suggestions, while also making the product more in line with market needs. On the basis of small-scale production tests and statistical data, small-batch trial production helps oxygen generator manufacturers to determine better processes through the evolution of a small amount of production, and provide a more stable production foundation during formal production, and also lay a good foundation for later product promotion and market expansion.

- Mass production link. According to the requirements of mold drawings, many parts that need to be assembled such as internal parts and electronic components of the body are produced, and these components are assembled according to the structural design requirements, and finally a stable and efficient oxygen generator is produced. In this process, it is necessary to operate in strict accordance with the ISO9001 production quality management system to ensure that the quality of each process reaches the corresponding level.

To sum up, in the whole process of product development, designers, manufacturers and engineers should strive for excellence in the internal and external design, structural design, prototype, mold and mass production of the product, to ensure that each oxygen generator is high-quality and efficient, and contribute to improving people's lives and improving production efficiency, and promoting the rapid development of the industry

We provide one-stop product development services:industrial design, mechanical design, rapid prototyping,small batch production,DFM,Mold design and manufacturing, Validation&Certification, mass production, etc

Others Cases

-

Smart Aquatics Feeding Machine

Innovative solutions for modern aquaculture industry

-

Home Vegetable Planter

The perfect combination of technology and green

-

Hongdu Weeder

LKK Design helps Jiangxi Hongdu Weeder product design and development

-

Innovative Dog Harness

We are not able to show more product images or disclose the names of our clients...

-

Smart Car Sunshade

We are not able to show more product images or disclose the names of our clients...

-

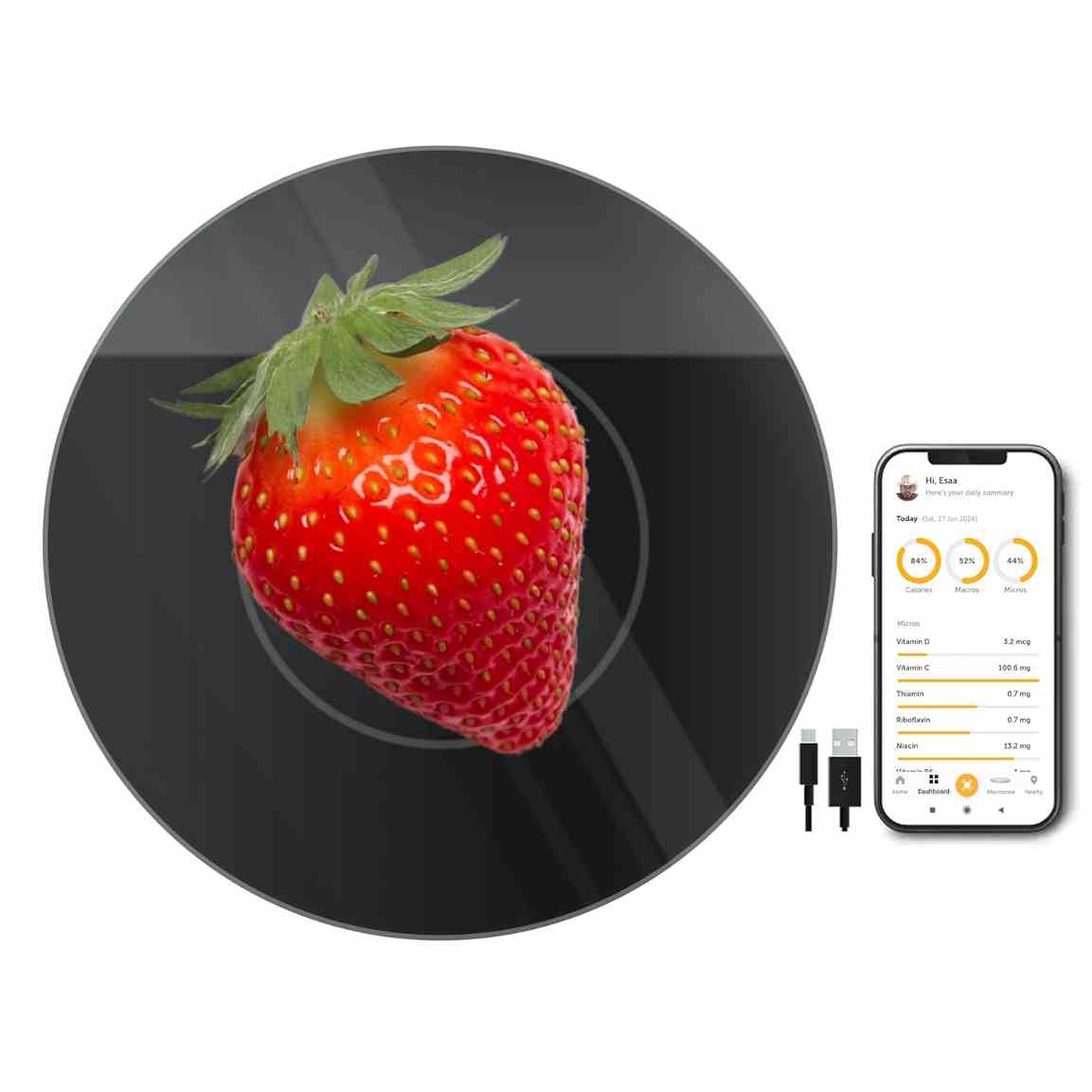

Smart(IOT) food scale

Product design and development of smart Bluetooth kitchen food scale

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025

The Designer Festival was successfully held at LKK Design

News April 2025

LKK Design Ushers in a New Chapter in Shenzhen: Driving Strategic Growth Through Product Design

Technical October 2024

LKK Design participated in the 90th Shenzhen International Medical Exhibition

News October 2024