GE Healthcare X-ray Digital Imaging Chest Rack

Work Efficiency & Comfort Pain Points – Before GE Healthcare X-ray Digital Imaging Chest Rack Product Development

As the most common medical device, X-ray digital imaging chest radiography accurately takes pictures of different injured parts of patients. This is to help the doctors make the correct diagnosis. The key to supporting the normal operation of the X-ray digital imaging chest radiography and meeting the requirements from different angles is the design of the equipment rack. It should allow the equipment to be adjusted to the required angle by the doctor according to the standing, sitting, and lying postures, and injured parts such as arm injuries, leg injuries and joint injuries of the patients. It is designed to improve the doctor’s work efficiency while maximizing patient comfort. However, a set of equipment that meets all the x-ray needs is challenging.

GE Healthcare X-ray Digital Imaging Chest Rack Product Design By LKKER SCM

As one of the world’s leading providers of medical products, GE is committed to solving universal problems. LKKER SCM and GE had jointly conducted an in-depth research on the design optimization of the X-ray digital imaging chest rack and came up with an innovative design solution that is the most user-friendly and meets the needs of GE products.

Highlight Features of GE Healthcare X-ray Digital Imaging Chest Rack

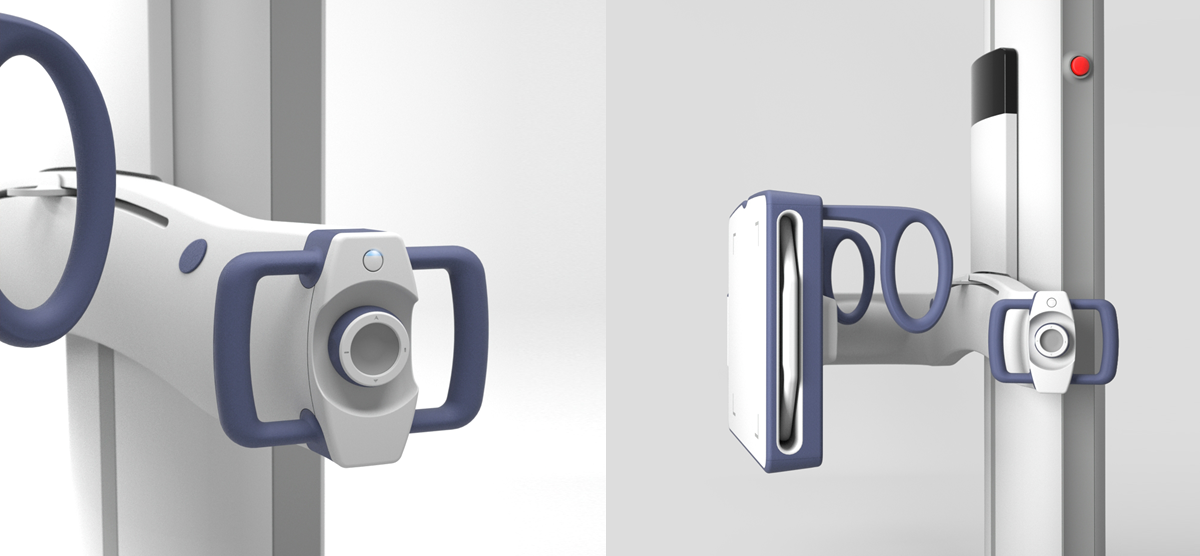

1.Generally, three ways of operation should be available for the doctors, one is a remote control, the other is machine button control, and the third is to quickly lift and stretch through the machine handle. When making an x-ray photograph for patients, the doctor may need to adjust the device repeatedly to achieve a photographic angle. Therefore, the very complicated adjustment requirements are one of the biggest challenges in this design.

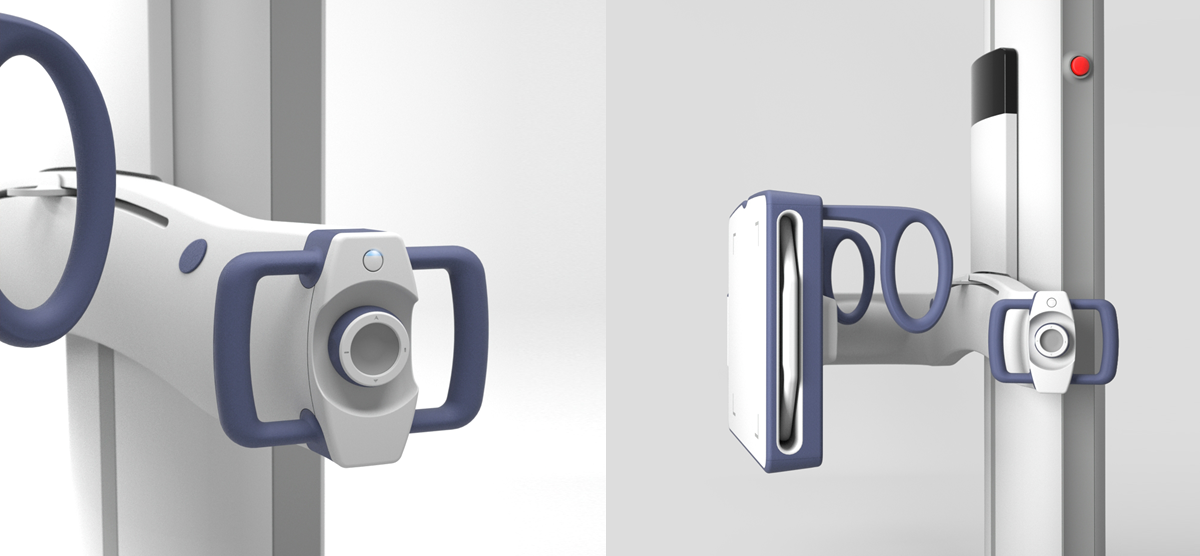

2.LKKER SCM starts from the convenience of the doctor’s use and combines the product performance to deliver a reversible geometry design. It simplifies the operation of the doctor and improves work efficiency.

3.It allows horizontal axis tilt mode, bed mode, and low mode. The doctor can perform basic operations by screen, handle, and manual operation.

4.Meanwhile, it allows multi-angle rotation including vertical axis rotation, horizontal rotation via the button at the bottom, and horizontal flip. The inward design of the control knob allows easy push of the knob and provides a comfortable experience when the detector moves up and down.

5. In terms of the display screen design, the screen displays readable information, which can not only ease the tension of the patient but also improve the efficiency of the doctor. The rigorous estimation ensures that the information is displayed at eye level.

User Experience Improved And Support Better Medical Operations

LKKER SCM team has helped GE implement and validate new ways to use vertical structures. The fly-by-wire system introduced by LKKER SCM not only reduces transmission chaos, enhances the user experience, but also subverts the operational design. Now, the information statistics is displayed at more appropriate height and the readings are easier. Moreover, it also marks a more established GE who is ready for a new era of humanization of medical equipment.

About LKKER SCM Product Design Service, Learn More >>>>

About GE Healthcare Learn More >>>>