Mechanical Design Buckles Design Standard

Buckles introduction The buckle position mainly refers to the buckle position of the upper shell and the lower shell. When considering the number and position of the buckle, it should be considered from the overall and external dimensions of the product. It is required to have an average number and a balanced position. The buckle …

Continue reading “Mechanical Design Buckles Design Standard”

Buckles introduction

The buckle position mainly refers to the buckle position of the upper shell and the lower shell. When considering the number and position of the buckle, it should be considered from the overall and external dimensions of the product. It is required to have an average number and a balanced position. The buckle located at the corner should be as close to the corner as possible to ensure better fitting at the corner. Seam problems are prone to occur at corners.

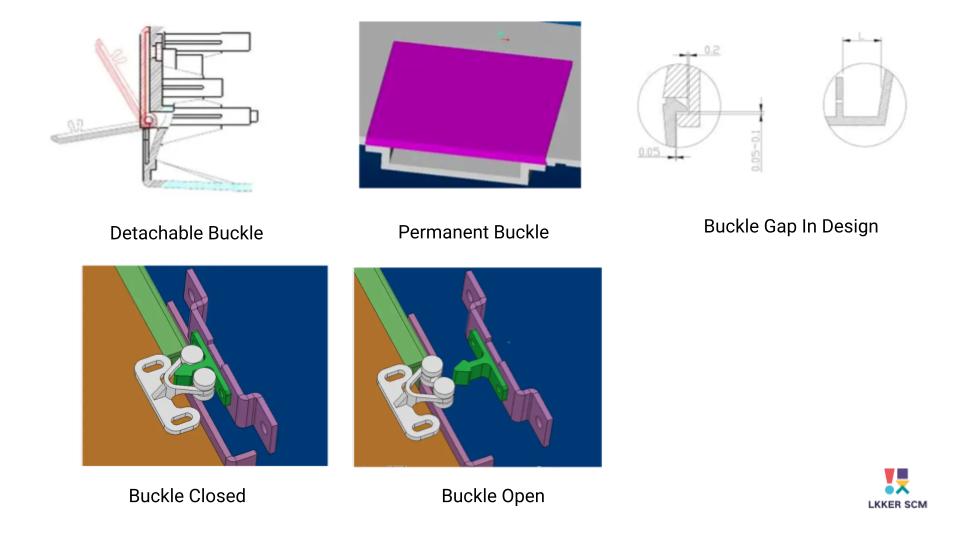

Classification of two buckles

Two classifications of deduction

(1) Detachable type

(2) Permanent

Generally, the buckles we commonly use are “removable”. The design of the permanent buckle is easy to install but not easy to remove, and the design of the detachable buckle is very convenient to install and remove. The principle is that the hook-shaped protruding part of the detachable buckle has appropriate lead-in and lead-out angles to facilitate the action of buckle and separation. The size of the lead-in and lead-out angles directly affects the force required for buckle and separation. The permanent buckle has only lead-in corners and no lead-out corners, so once it is buckled, the connected parts are in a self-locking state, and it is not easy to remove.

Four buckle design considerations

The buckle is the easiest, fastest, lowest cost, and most environmentally friendly way to assemble plastic parts. There is no need to use auxiliary tools such as screwdrivers during buckle assembly, and the assembly process is simple, and the assembly of two or more parts can be completed with a simple insertion action. Before designing the buckle, it is necessary to understand the following important factors: the mechanical properties of the plastic material used; the number of times of assembly and disassembly; the stress that the buckle can withstand during the assembly process, and the mechanical pressure acting on the buckle after assembly.

1. The size of the buckle, the size of the buckle needs to ensure that the buckle has sufficient strength and elasticity so that the buckle has sufficient strength and elasticity so that the buckle will not break and fail during the assembly or disassembly process, so the reasonable size of the buckle is very important. The thickness and height of the buckle are the main factors that determine the strength and elasticity of the buckle. If the thickness of the buckle is too small, the strength is weak, and the buckle cannot withstand large resistance; if the thickness of the buckle is too large, the buckle is not elastic, and it will break due to insufficient offset during the assembly process. Plastic walls are prone to shrinkage defects.

Different plastic materials have different dimensions of the buckle due to their different elastic modulus and other parameters. The required buckle size can be calculated by the relevant formula. Of course, the best way is to verify whether the size design of the buckle meets the stress requirements through finite element analysis.

2. Add rounded corners at the root of the buckle to avoid stress concentration. The most common failure mode of the buckle is due to the sharp connection between the root of the buckle and the wall of the part, which leads to the concentration of stress at the root of the buckle so that it breaks during the assembly or disassembly process. Some buckles need to avoid sharp corners at the root, and at least ensure rounded corners half the thickness of the buckle.

3. The buckles are evenly distributed if the two parts are matched by the buckles, the buckles need to be evenly arranged around the parts to bear the load evenly. If the part is prone to deformation, consider placing the buckles close to places where the part is prone to deformation, such as the corners of the part.

4. Use the positioning column to assist the assembly of parts and ensure the dimensional accuracy of the assembly. If the parts are completely matched by buckles, it is difficult to ensure the assembly accuracy requirements between the parts due to the low dimensional accuracy of the buckles. This is the disadvantage of buckle-fit. At this time, the positioning column and positioning hole can be added to ensure the assembly size between the parts and improve the assembly accuracy. There are two other benefits of using locating posts and locating holes. First, during the assembly process of the two parts, the positioning column and the positioning hole of the appropriate height are first in contact with the buckle assembly feature (that is, the height of the positioning column on the plastic part is higher than the height of the buckle), which can be the assembly process of the parts provides guidance and improves the assembly efficiency. At this time, the role of the positioning column plays a guiding role; secondly, the use of the positioning column can effectively avoid the buckle damage caused by the rough assembly action.

5. The buckle design avoids increasing the complexity of the mold. The unreasonable buckle design can easily increase the complexity of the injection mold, and the parts need a lateral core-pulling mechanism, which increases the cost of the mold. Proper buckle design optimization can simplify the mold structure. The undercut can be avoided in the main part of the buckle, and the injection mold does not need a lateral core pulling mechanism.

6. The buckle design needs to consider the convenience of mold modification. The buckle design generally requires multiple design modifications (including modifying the length, thickness, offset, etc. of the buckle) to meet the assembly requirements of the parts. The design size can be slightly smaller, instead of making the size of the buckle enough at one time, it is convenient for subsequent mold modification.

Learn More

LKKER SCM Mechanical Design Service

LKKER SCM Design For Manufacturing (DFM) Service