The "Wentian" lab module was successfully launched in July 2022. As an important part of the "Tiangong" space station, the "Wentian" lab module is the second largest lab module launched to the space station after the "Tianhe" core cabin module. LKK was once again involved in the product design and manufacturing project for the aerospace industry and successfully contributed to the development of the airspace station.

As the first space station project in China, Tiangong Space Station is undertaken by the Design Department of China Aerospace Science and Technology Corporation to undertake the research task of the material management subsystem of the space station. Committed to in-depth aerospace in the direction of space habitability technology, from the exploration of the "Tianhe" core cabin to the "Wentian" lab cabin, the Design Department of China Aerospace Science and Technology Corporation will improve and optimize the space living environment of astronaut step by step.

In the development of a cabin whose weight will affect the rocket launch results, how to create a more comfortable and possibly occupied space for astronauts under the specified volume and weight has become the primary problem to be overcome in the long-term stay at the space station.

LKK is entrusted by the Design Department of China Aerospace Science and Technology Corporation, to work together to create a more comfortable living space.

Service Scope

01 Body Limiting Device

Body Limiting Device

Product Design Highlight:

Since the phenomenon of weightlessness in space brings great trouble to astronauts in both work and living, how to comfortably fix the body to prevent floating when working in the cabin is an important consideration in the design of body-limited devices. This product can be used to fix different postures such as sitting and standing without the need for a seat cushion. After the legs are fixed with straps, the angle, height, width, etc. of the legs can be adjusted quickly and easily, and they can be quickly folded and stored without taking up space.

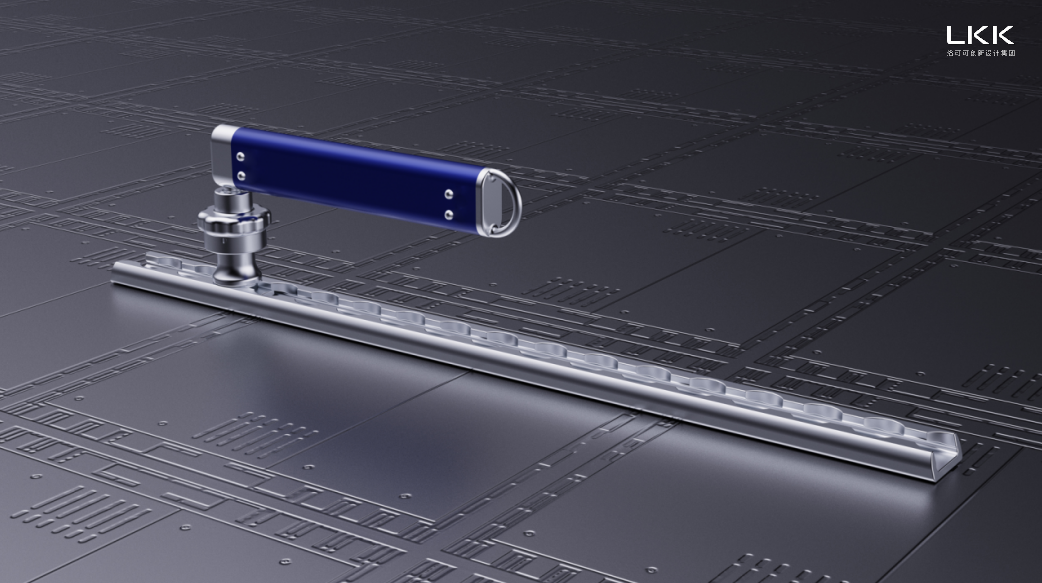

Mobile Foot Limiter

Product Design Highlight:

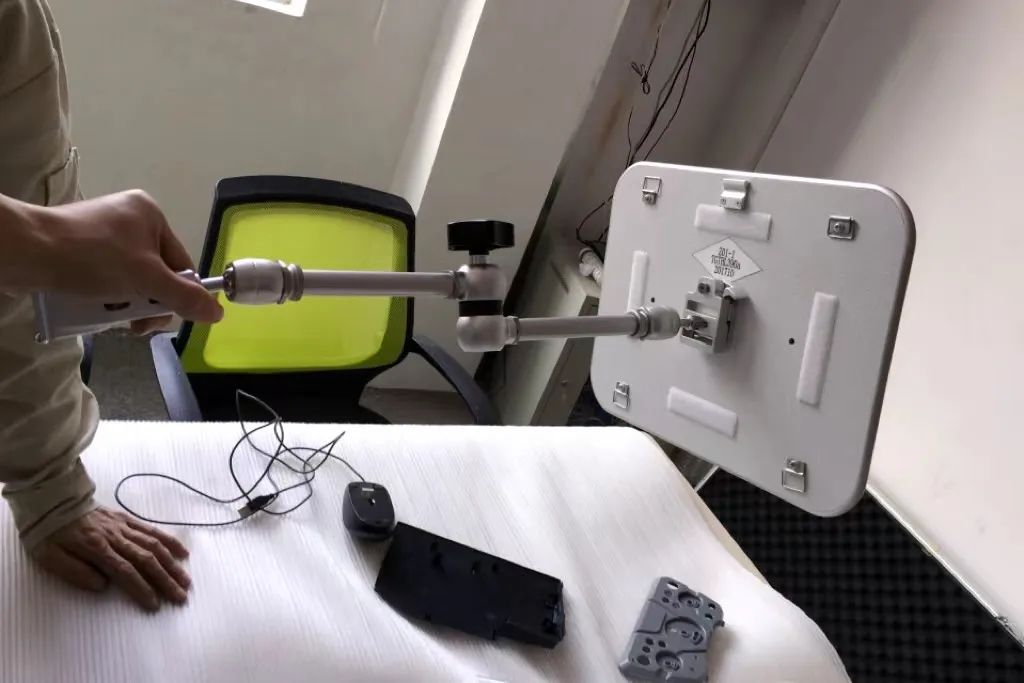

A device for astronauts to fix their feet in the cabin. It stands at different positions in the cabin space, which is convenient for astronauts to fix their positions. Without using extra tools, it can be quickly fixed with various handrails and telescopic rods on the cabin wall.

02 Handrail device

Product Design Highlight:

Mobile long handrails, short handrails, telescopic handrails; fixed short handrails, long handrails, curved handrails, and a series of handrail devices are all fixed on the cabin wall or cabin wall track, which can be quickly installed and can be used with fixed mobile workbench, Mobile foot limiter, and other equipment.

03 Workbench

Mobile Workbench

Product Design Highlight:

It is used by astronauts to fix laptops and devices or equipment in the cabin. The clamps at the fixed end are adapted to all the armrests in the cabin and are composed of multiple joints. Only the adjustment knob can tighten all the degrees of freedom, and it can be used without borrowing tools. It can be used for quick blessing in any situation, and it can be folded as a whole without taking up space when not in use.

Fixed Workbench

Product Design Highlight:

The fixed workbench is used for astronauts to take notes in the cabin, or to fix small equipment such as tablet computers. It can be easily and quickly fixed and adjusted, and can be folded when not in use. It is light in weight and takes up less space.

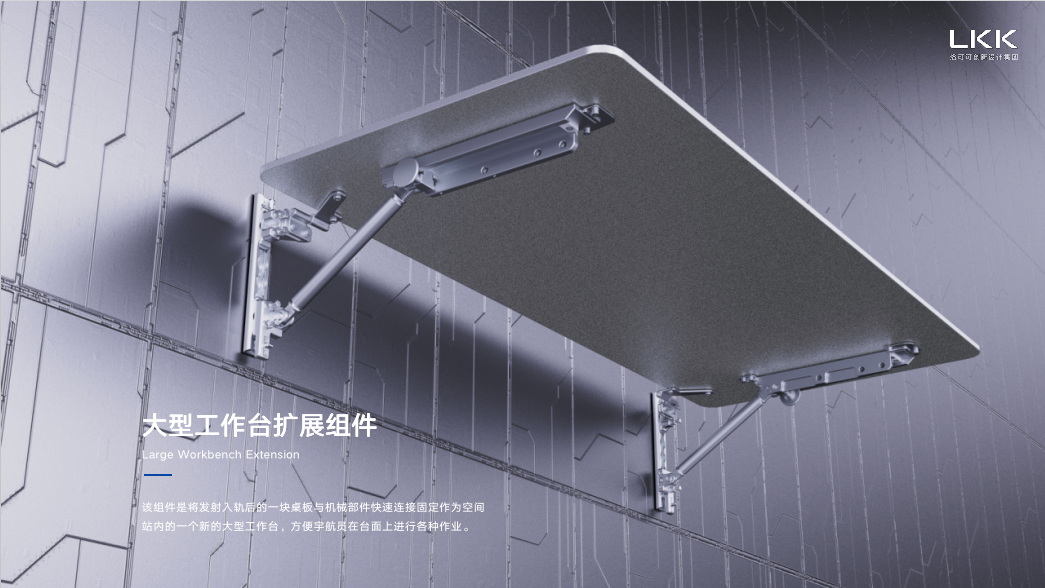

Large Workbench Extension

The large workbench extension is a set of mechanical parts. After launching into orbit, the table board can be quickly linked and fixed with the mechanical parts. As a new large-scale workbench in the space station, it is convenient for astronauts to perform various operations on the table.

Main DiningTable And Extension Dining Table

It is used for dining at the table and can also be used as large table utensils, and can also be used as large furniture and different parts of the extended dining table or different desktop parts.

More than a thousand pieces of equipment produced by the LKK Shenzhen team (LKKERSCM) have been successfully put into use.

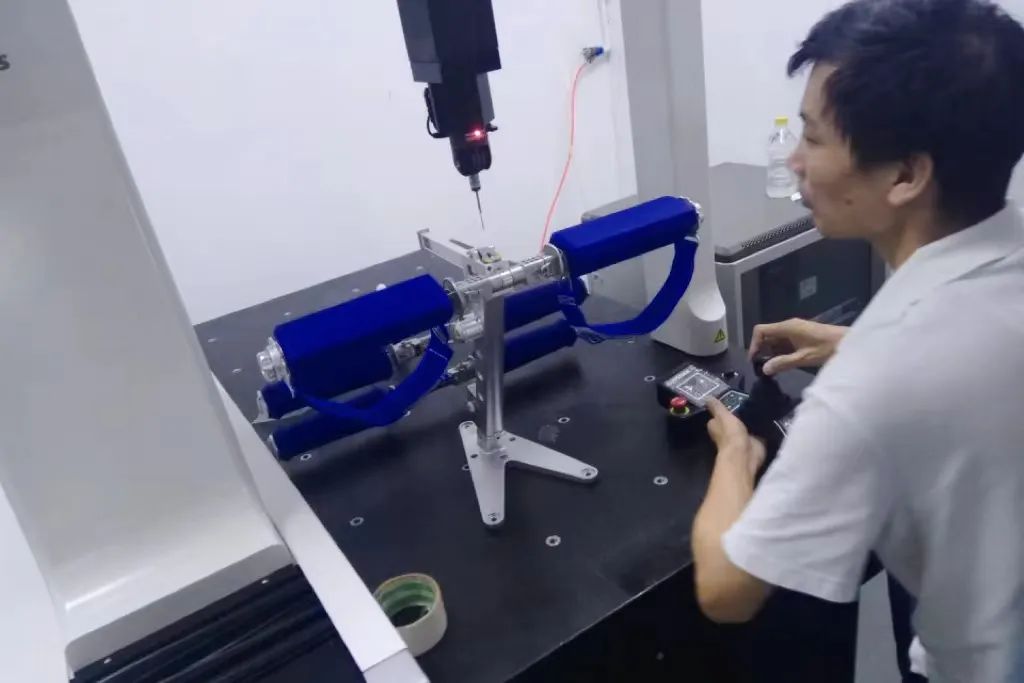

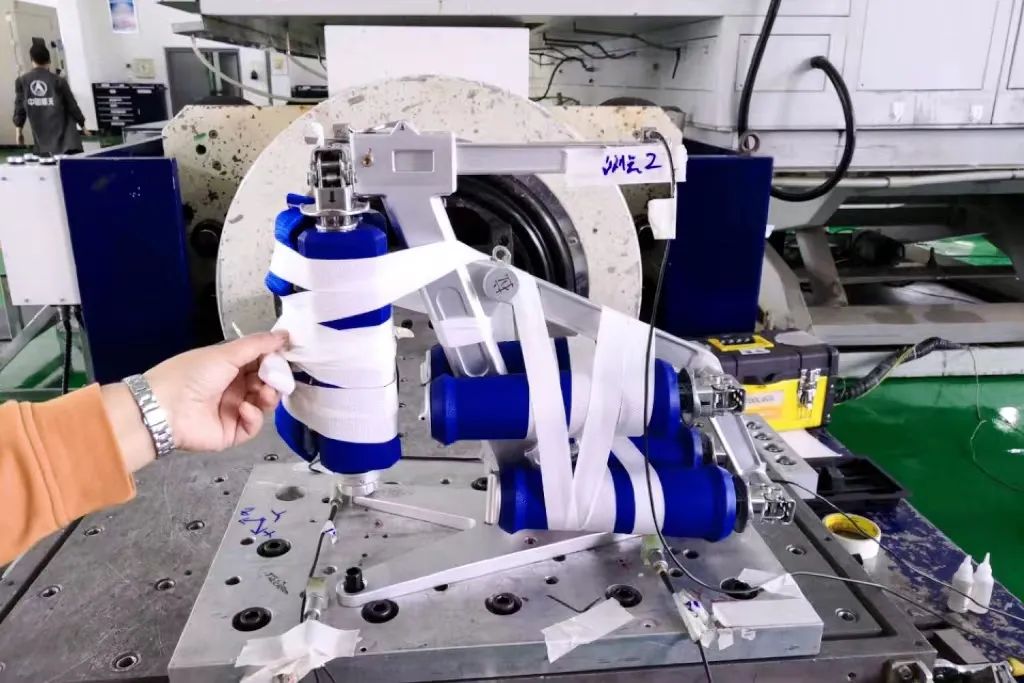

Error Must Be Zero

In aerospace systems engineering, quality is the life and responsibility of project members. All produced products do not have a pass rate or delivery interval. We must achieve 100% without any minor errors. Even if there is an error of 0.01mm, it will be magnified countless times in aerospace, causing unpredicted damage or difficulty for astronauts.

The aerospace project has strict limits for weight and volume. The products we deliver, save a little more space, can give astronauts a more comfortable range of activities and reduce a little more weight, and can add more chances to a successful rocket launch.

First of all, after hundreds of adjustments to optimize the design of the structure, while ensuring the function, product strength, user usability, durability, and safety are as high as possible;

Secondly, the product needs to ensure low weight and less space, and it must also be easy to expand and use with other equipment. Each stand-alone product goes through four design and production verification stages: initial prototype, structural thermal control, identification, and prototype for approval to implement;

Then, the finished product will undergo a long-term vibration test on the vibration table that simulates the rocket to ensure that the final product will be designed and manufactured with zero defects.

Finally, the products must be in accordance with the "Space Station Product Design and Construction Specifications" to ensure that each product entering the aviation cabin has a laser engraving number (data package information) to ensure the quality of the whole process can be traced.

About LKKER SCM

LKKER SCM Co., Ltd is a member company of LKKdesign Group, 100% owned by LKKdesign Group which is founded in 2004. LKKER SCM is a one-stop product development and customized supply chain solution provider. We offer services from design to manufacturing covering industrial design, mechanical design, electronics engineering, rapid prototype, tooling, pilot production, and mass production. LKKER SCM has been recognized as Indiegogo Recommended Prototyping & Manufacturing Expert since 2019.

LKKdesign Group is a regular product design award winner worldwide. Being the largest and top-tier design house in China, LKK has won 521 design awards since company establishment. LKKdesign is recognized as the National Industrial Design Center by The Ministry of Technology since 2013. Key investors of LKKdesign include Fortune Capital, China Culture Industrial Investment Fund, and Green Pine Capital Partners.

LKKER SCM partners with you to develop your product and get it to market quickly, efficiently, and economically. We have the design expertise, engineering knowledge, and manufacturing know-how to tailor solutions that work for you and your product in these sectors:

|

Turnkey designs Electronic Design Mechanical Design Assembly Process Design Metal & Plastic Enclosure DFM Certification Support Prototypes Builds NPI Project Management |

Supply Chain Development Cost Down Solution Alternatives Solution QC, QA, and Delivery Manufacturing Operation Supplier Management Presence in China Transfer to High Volume Manufacturing Ship Direct to Customers |

Latest

October 2024

LKK and HHOGene launch world's first light-controlled TWS earbuds

Technical April 2025

LKK Design Wins 8 Red Dot Awards in 2025

Technical March 2025

The Designer Festival was successfully held at LKK Design

News April 2025

LKK Design Ushers in a New Chapter in Shenzhen: Driving Strategic Growth Through Product Design

Technical October 2024

LKK Design participated in the 90th Shenzhen International Medical Exhibition

News October 2024